📍Bergen County Specialists

30 years serving local homes and businesses

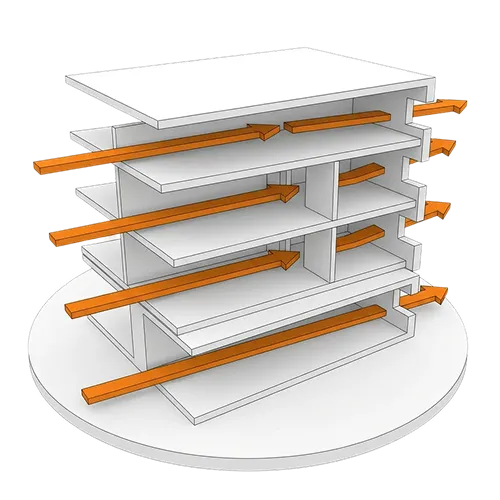

Commercial Structural Drying — Advanced structural drying systems for commercial buildings.

60 Minute Response

Average arrival across Bergen County—24/7/365

Professional Team

30+ Years Experience

$2M Insured

Complete Protection

Direct Billing

No Out-of-Pocket Cost

A+ Rating

Better Business Bureau

24/7 Emergency

Always Ready to Help

Large-scale structural drying minimizes downtime and protects building systems, finishes, and inventory after water intrusion events.

A recently poured slab in a retail fit-out retained excessive moisture due to prolonged curing and unexpected groundwater seepage. Flooring installation was delayed as adhesive and finish required moisture below specified limits, threatening the tenant move-in schedule.

Our Solutions:

A failed chilled-water pipe in a rooftop mechanical room flooded equipment and adjacent control panels, damaging insulation and saturating structural framing. Rapid drying was required to prevent corrosion and to restore HVAC operation for tenant comfort.

Our Solutions:

A burst water main on the service corridor flooded corridors and tenant spaces across two floors, soaking ceiling cavities, insulation, and suspended grid systems. The priority was to reopen high-traffic retail zones while drying damaged common-area ceilings and tenant storefronts.

Our Solutions:

See how we've helped local homes and businesses

Commercial Structural Drying

Flooding saturated walls and structural cavities in a multi-tenant commercial property requiring industrial drying and documentation for insurance.

Installed structural drying systems, drilled and injected wall cavities where necessary, deployed desiccant dehumidifiers, and provided daily moisture logs to stakeholders.

Structural moisture returned to safe levels within one week and building reopened to tenants with minimal disruption.

Targeted Structural Drying

Concealed moisture in wall cavities after sprinkler activation threatened prolonged drywall damage and mold growth across multiple tenant suites.

Used targeted injection drying and cavity access points, continuous monitoring, and desiccant dehumidification to remove trapped moisture without full demolition.

Walls dried to acceptable moisture levels within 5 days, avoiding costly full demolition and accelerating tenant re-occupation.

Need similar help? We're ready 24/7

Call (201) 500-2332Local expertise, fast response, and clear communication

30 years serving local homes and businesses

Based in Hackensack with crews ready 24/7

Industrial-grade tools and technology

Preferred vendor for State Farm, Allstate, Liberty Mutual

One call coordination across tenants, vendors, and insurance to minimize disruption and resolve issues fast.

Clear communication across stakeholders

Coordinate crews and building services

Transparent reporting and claims support

Reduce future incidents and risk

Need coordinated property support? Call us 24/7 or Speak with our coordination team

4.9/5 stars from 500+ Google reviews

Complex slab drying—clear moisture data, GC coordination. Final readings perfect—no demolition needed.

Meredith C.

Teaneck, NJ

Professional & consistent monitoring. Daily logs helped plan reconstruction smoothly.

Victor N.

Fort Lee, NJ

Excellent drying plan. Equipment noise expected. Fixed moisture & detailed closeout.

Alicia W.

Lyndhurst, NJ

Everything you need to know

We deploy industrial desiccant dehumidifiers, large-frame air movers, injected cavity drying systems, mat drying for concrete, and continuous moisture monitoring. Equipment selection is driven by materials (concrete, plaster, raised floors) and project scale to achieve ASTM-compliant drying rates.

We use sub-slab or mat drying coupled with desiccant systems and controlled injected airflow to accelerate moisture removal. In many cases we avoid full slab demolition by combining surface grinding, mat systems, and extended drying with documentation for contractor sequencing.

We provide daily moisture logs using calibrated meters, thermal imaging evidence, and a final drying completion report showing material readings within acceptable tolerances. These records support insurance approvals and guide the reconstruction schedule.

Yes—our project managers coordinate sequencing with general contractors, MEP trades, and facility teams so drying and build-back proceed without re-exposing materials. We provide staged sign-offs to allow partial reoccupation while other areas remain under drying.

We're standing by 24/7.